ARMS (Advanced Registration Mark Sensing system) to fifth generation

Enhanced ARMS, improved precision cutting and productivity in Print & Cut application

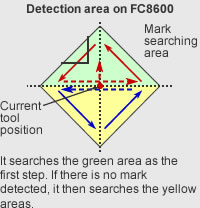

Auto mark detection

The first registration mark is automatically detected within a wide search area; this eliminates the need to manually move the sensor near the registration mark position. Subsequent marks are automatically located which improves the operation of the registration mark searching.

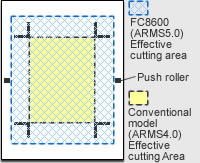

Expanded cutting area

The new ARMS 5.0 expands the cutting area to include the area outside the registration marks. This increases the production efficiency by reducing media waste.

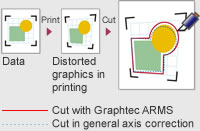

4-point axis alignment

This feature compensates for any direction on the X-axis and Y-axis using sophisticated algorithms. This leads to more accurate registration and improves the reliability and quality of Print & Cut.

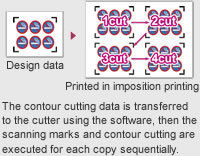

Multiple-mark compensation

When the design is printed with the matrix copy function, the action of reading the marks and contour cutting is repeated for each copy. It significantly improve productivity for Print & Cut.

* This function is available when the Graphtec Studio, Graphtec Pro Studio, Cutting Master 2/3/4 software is used.

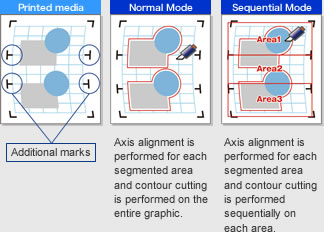

Segment area compensation

A 4-point axis alignment is performed for each segmented area.

In Normal Mode, this is performed by reading the marks in the middle of the feeding direction for the entire graphic and then cutting the entire graphic, providing high-precision alignment for long length Print & Cut applications.

In the new Sequential Mode, contour cutting is performed sequentially in each segmented area. Media movement is limited to the smaller area being cut, improving accuracy and tracking for heavier media or media that has been laminated.

* Normal mode is available when Graphtec Studio, Graphtec Pro Studio, Cutting Master 2/3/4, or Plotter Controller software is used.

* Sequential mode is available when Graphtec Studio (ver. 2.1.200 or later) or Cutting Master 3 (ver. 2.1.211 or later) is used.

* This function is available in firmware version 2.10 or later.

Auto sensitivity adjust

The sensitivity of the registration mark sensor is automatically set by measuring the reflective level of the mark and the background of the actual media. The mark can be detected when the colour of the mark has a reasonable contrast against the background. For example, a white mark can also be detected on a coloured background.

ISM (Intelligent Scan Mode)

The ISM incorporates a new scanning algorithm that not only expands the cutting range of compatible media, but also reduces scan times and increases mark scanning success. Registration marks are also detectable on colored media and textured media, such as glossy laminated materials that were difficult using the conventional method.

* Media must be within the specification in range. Marks may not be detected due to poor print quality or media surface.

* This function is available in firmware version 2.10 or later.

Supports ARMS commands

Improved application software

Including improved design application software (Graphtec Pro Studio) and plug-in software for Illustrator and CorelDRAW (Cutting Master 4)

Design application software

Graphtec Pro Studio / Graphtec Pro Studio Plus

Easy-to-use application software for creating original designs. It has enhanced functions such as auto-shapes, shading, and editing functions. It can also configure the cutting conditions and other settings on the plotter. Importing of EPS, Ai, CMX, and PDF file types are supported. Graphics created with other popular design software can be imported into the software.

Easy-to-use application software for creating original designs. It has enhanced functions such as auto-shapes, shading, and editing functions. It can also configure the cutting conditions and other settings on the plotter. Importing of EPS, Ai, CMX, and PDF file types are supported. Graphics created with other popular design software can be imported into the software.

Show Details

< Supported OS (*) >

Windows 10 / 8.1 / 8 / 7

Plug-in software for Illustrator & CorelDRAW

Cutting Master 4

Cutting Master 4 is Graphtec plug-in software for Adobe Illustrator and CorelDRAW Graphics Suite. It sends cut data to the plotter and includes a variety of functions such as: preview, registration mark creation, tool conditions, cut job settings and more. Cutting Master 4 is easy to use and enables you to get the best performance from your plotter.

Cutting Master 4 is Graphtec plug-in software for Adobe Illustrator and CorelDRAW Graphics Suite. It sends cut data to the plotter and includes a variety of functions such as: preview, registration mark creation, tool conditions, cut job settings and more. Cutting Master 4 is easy to use and enables you to get the best performance from your plotter.

Show Details

< Supported OS (*) >

Windows 10 / 8.1 / 8 / 7

Mac OS X 10.7 to 10.11 / macOS 10.12 (Sierra)

< Supported software (*) >

Illustrator :

CC2017/CC2015.3/CC2015/CC2014/CC/CS6/CS5/CS4 (Supporting CS4 is the only Windows OS),

CorelDRAW:

Graphics Suite X8/X7/X6/X5/X4

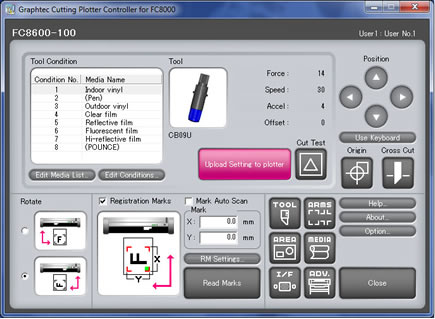

Plotter control software

Plotter Controller

This software can control various settings of the FC8600 from a PC, improving work and operating efficiency. This controller can be started from the plotter driver when the print operation is executed by the Print menu of the application software. It can be run concurrently with the design software so the design and cutter control windows are open to smoothly run a series of tasks from image design to cutting media.

< Main Features >

- Configuring the cutting conditions

- Executing the test cut

- Setting the parameter for the ARMS and executing the ARMS functions

- Setting the rotation of the data (to match the direction of loaded media)

- Moving the tool position

- Setting the origin of the plotter

- Operation with the short-cut keys

< Supported OS (*) >:Windows 10/8.1/8/7/Vista