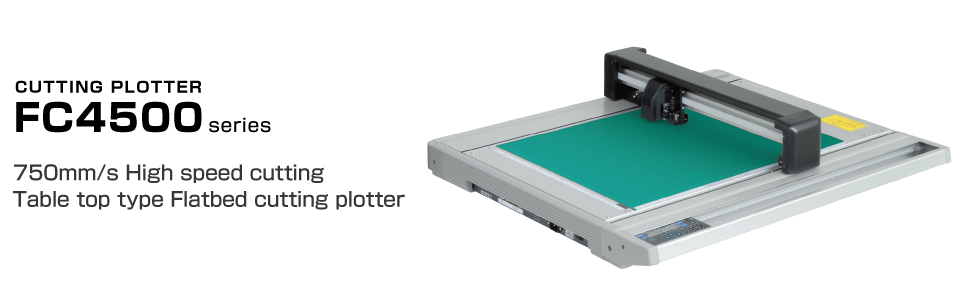

General

Maximum cutting speed is 750mm/s

Table top type cutting plotter with excelent cost performance

Flatbed cutting plotter is used for not only sign making but also for a wide range of industrial applicaitons and processes. Max.750mm/s cutting speed is useful for getting high productivity.

*1:For Macintosh, It needs to be used the Cutting Master 4 that is plug-in software for Illustrator.

Main Features

Table top type cutting plotter with max.750 mm/s cutting speed

The FC4500 Series are professional flatbed cutting plotters capable of processing a wide variety of materials with accuracy. Compact size that can be set on a table with precise control of contour cut, half cut,perforated cut, and plotting.this FC4500 series is the most economical solution for cutting thick, hard materials that cannot be fed through a grit rolling type cutting plotter.

The FC4500 Series are professional flatbed cutting plotters capable of processing a wide variety of materials with accuracy. Compact size that can be set on a table with precise control of contour cut, half cut,perforated cut, and plotting.this FC4500 series is the most economical solution for cutting thick, hard materials that cannot be fed through a grit rolling type cutting plotter.

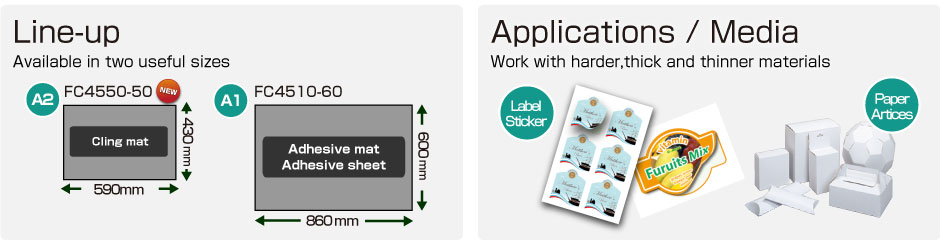

Media hold-down method

It is very important to select exact media hold-down method in order to perform a precise cut. FC4500 series provide the following method to fit a variety of media.

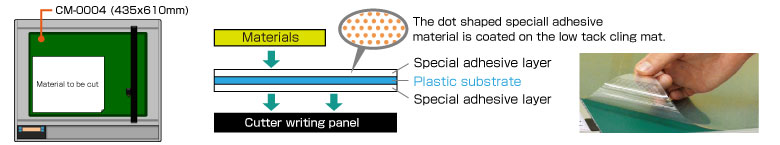

NEW! Low tack cling mat (CM-0004)

The media is held by the dot shaped adhesive material on the low tack cling mat

Suitable materials (media)

- Highly-functional film - Highly-functional film (with backing sheet)

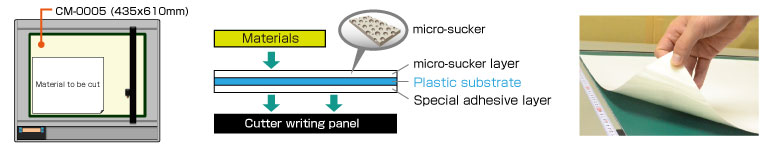

NEW! Micro suction cling mat (CM-0005)

The media to be cut is held to the cutter by the micro-sucker on the cling mat.

Suitable materials (media)

- Marking film- Labels, stickers - High-intensity reflective film - Cardboard (Paper articles, POP, POD)

- Micro flute board (F/G grades) - High-quality/grade paper (Marking)

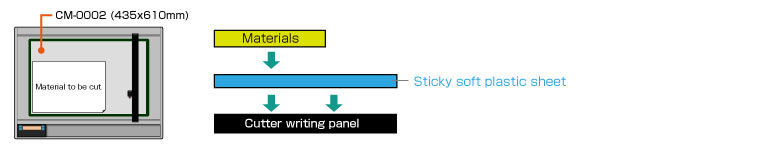

Adhesive mat (CM-0002)

The media to be cut is held to the cutter by the sticky soft plastic mat.

Suitable materials (media)

- Coated cardboard for paper articles - Micro Flute board for package

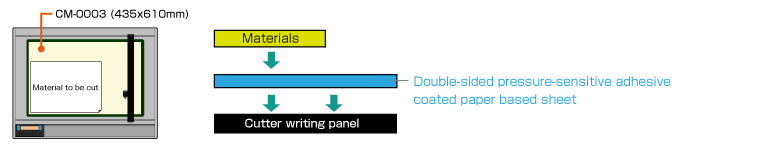

Adhesive sheet (CM-0003)

The media to be cut is held to the cutter by the pressure-sensitive adhesive on the adhesive sheet.

* Supplying in roll. It is used by cutting to the required size.

Suitable materials (media)

- Marking film, PVC (Vinyl) - Labels/stickers, Film/paper - High-intensity reflective film - Cardboard (Paper articles, POP, POD)

- Paper with lamination - Micro flute board (F/G grades)

| Material (Media) | CM-0004 (Low tack type) | CM-0005 (Micro suction type) | CM-0002 (Adhesive mat) | CM-0003-R1A (Adhesive sheet) |

|---|---|---|---|---|

| PVC (Vinyl) film for Marking, Sign | No good (*1) | Excellent | N/A | Good (*2) |

| Film / paper for label or sticker | No good (*1) | Excellent | N/A | Good (*2) |

| High-intensity reflective film for SIgn | No good (*1) | Excellent | N/A | Good (*2) |

| Cardboard for POP | No good (*1) | Excellent | N/A | Good (*2) |

| Coated cardboard for POP | No good (*1) | Excellent | N/A | Good (*2) |

| Paper with lamination for POS | No good (*1) | No good | N/A | Excellent |

| Coated cardboard for paper articles | No good (*1) | Excellent | Excellent | Good (*2) |

| Micro Flute board for package | No good (*1) | Excellent | Excellent | Good (*2) |

| Highly-functional film with backing sheet for Industry | Excellent | Very good | N/A | Good (*2) |

| (CM-0004 is suitable) | ||||

| Highly-functional film for Industry | Excellent | Very good | N/A | Good (*2) |

| (CM-0004 is suitable) | ||||

| Stiff paper / card for Garment, Shoes | No good (*1) | Excellent | N/A | Good (*2) |

| High-quality paper for marking | No good (*1) | Excellent | N/A | N/A |

- note

- Assessment varies by the material. There is different characteristic materials in the same category. Please evaluate with the material that is actually used.

- *1

- Adhesive force will be weakened by the paper dregs in not many cuts. The mat needs to be frequently replaced. Do not recommend for this material.

- *2

- It may occur curling of the material by strong stickiness when it is peeled off from mat.

Advanced Registration Mark Sensing system (ARMS)

Increase the productivity of the Print & Cut

Graphtec’s ARMS system adjusts for several types of potential print distortions, allowing for accurate contour cutting of pre-printed images and decals.

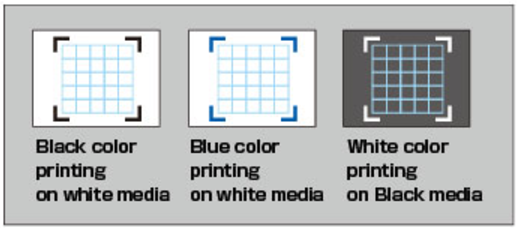

Automatic sensor sensitivity adjustment

Automatic sensor sensitivity adjustment

Not only black color on white media, such as blue color mark can be read it the color has contrast. It also reads in the data that has beed inverted such as white mark on a black media

*Various combination of colors may not be able to read

Fours-points registration mark correction

Fours-points registration mark correction

Four-points registration mark sensing and X/Y axis correction uses high precision positioning to ensure accurate cutting of graphics that have beed skewed or deformed during printed.

Segment area compensation

Segment area compensation

The intermediate registration mark in the X-axis direction allow four-points correction for each individual segment area. This enable precise positioning over the whole area of prints that may have skewed during the printing process

Multiple registration mark set detection

Multiple registration mark set detection

The cutting data and layout information are sent for designs printed in multiple copies, enabling continuous detection of registration marks for cutting. This feature is essential when high accuracy cutting is required

Auto registrtion mark detection

Auto registrtion mark detection

The first registration mark is detected automatically, eliminating the need to move the head to the registration mark manually. Should registration marks not be found at the first attempt they are automatically re-detected, thus saving the time of starting over.

Supports registration mark commands

Supports registration mark commands

Registration mark commands are provided to control ARMS functions from software.

Advanced reverse-side cutting / creasing function

Cutting and creasing can be carried out from reverse-side when using the registration marks.

This function prevents a cutting / creasing line from appearing on the printed surface.

Enhanced functions for higher productivity

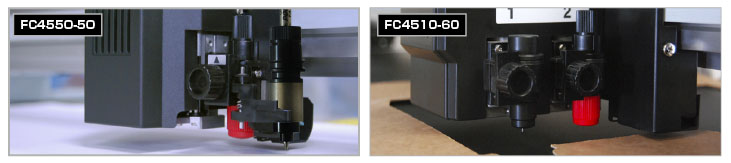

2-Tool holders for easy selection.

Two tools can be mounted at the same time for easy switching. If the cutter blade and the creasing tool are mounted at the same time, cutting and scoring operations are performed automatically for higher productivity.

Note: The second tool is held by magnetic force on the FC4550-50, so the choice of tool is limited.

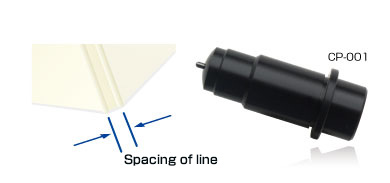

Simple creasing function

A simple function to create fold lines for clean folding on micro-flute and cardboard has been enabled.

-) Up to thre fold lines can be selected

-) If two or three fold lines have been selected, the spacing between the lines can also be specified.

-) Repeated creasing operations can also be specified for each of the lines.

How too determine the number of creasing lines

-) Single-line : Substrates up to 0.1 mm thick

-) Double-line : Paperboard 0.1 to 0.5 mm thick

-) Triplee-line : Rigid cardboard 0.3 to 0.5 mm thick

Multi pass cut function

This function enable to perform the cut with multi pass on a media that cannot be cut

with a single cutting operation.ensuring sharp edges and corners.

Tangential emulation

Graphtec's proprietary tangential emulation provides precise and clean cutting even on thicker material,

ensuring sharp edges and corners.

Software

Graphtec Pro Studio / Graphtec Pro Studio Plus

Design application software

Easy-to-use application software for creating original designs. It has enhanced functions such as auto-shapes, shading, and editing functions. It can also configure the cutting conditions and other settings on the plotter. Importing of EPS, Ai, CMX, and PDF file types are supported. Graphics created with other popular design software can be imported into the software.

Easy-to-use application software for creating original designs. It has enhanced functions such as auto-shapes, shading, and editing functions. It can also configure the cutting conditions and other settings on the plotter. Importing of EPS, Ai, CMX, and PDF file types are supported. Graphics created with other popular design software can be imported into the software.

Supported OS : Windows 10/8.1/8/7

Cutting Master 4

Plug-in software for Illustrator & CorelDRAW

Cutting Master 4 is Graphtec plug-in software for Adobe Illustrator and CorelDRAW Graphics Suite. It sends cut data to the plotter and includes a variety of functions such as: preview, registration mark creation, tool conditions, cut job settings and more. Cutting Master 4 is easy to use and enables you to get the best performance from your plotter.

Cutting Master 4 is Graphtec plug-in software for Adobe Illustrator and CorelDRAW Graphics Suite. It sends cut data to the plotter and includes a variety of functions such as: preview, registration mark creation, tool conditions, cut job settings and more. Cutting Master 4 is easy to use and enables you to get the best performance from your plotter.

Supported OS : Windows 10/8.1/8/ 7、Mac OS X 10.7 to 10.11 / macOS 10.12 (Sierra)

Supported software Illustrator :

CC2017/CC2015.3/CC2015/CC2014/CC/CS6/CS5/CS4 (Supporting CS4 is the only Windows OS),

CorelDRAW Graphics Suite X8/X7/X6/X5/X4

Graphtec Studio for Mac OS

This is an easy-to-use application software for Mac OS to create original designs.

This is an easy-to-use application software for Mac OS to create original designs.

Images can be easily created by using the program icons that are arranged around the drawing area.

Supported OS : Mac OS X 10.6 to 10.11 / macOS 10.12 (Sierra)

Specifications

Specfications

| Model name | FC4550-50 | FC4510-60 |

|---|---|---|

| Configuration | Digital servo system, Flatbed | |

| Media hold-down method | Cling mat | Adhesive sheet / mat |

| Effective cutting area | 590 x 430 mm (23.2 x 16.9 inch) | 860 x 600 mm (33.8 x 23.6 inch) |

| Mountable media | 500 mm (19.6 inch) (Y-axis direction) |

666 mm (26.2 inch) (Y-axis direction) |

| Media type | Marking film (vinyl, fluorescent, and reflective) Stiff paper/card (for stencils, etc.) up to 0.5 mm thick *1 Polystyrene foam sheets up to 0.8 mm thick *2 Sandblast rubber sheets up to 1.0 mm thick *2 Microflute board (F/G grades) Clear sheets for plastic boxes High-intensity reflective film *3 |

|

| Maximum cutting speed | 750 mm/s (30 inch/s) (1 to 75 cm/s in 23 steps) | |

| Cutting pressure | Tool 1: Max. 5.88 N (600 gf), in 48 steps Tool 2: Max. 2.94 N (300 gf), in 30 steps |

Tool 1, Tool 2: Max. 5.88 N (600 gf), in 48 steps |

| Minimum character size | approx. 5 mm square (varies with the character font and media) | |

| Mechanical resolution | 0.005 mm (5μm) | |

| Programmable resolution | GP-GL mode: 0.1/0.05/0.025/0.01 mm, HP-GL™ *4 : 0.025 mm | |

| Distance accuracy | Max 0.2% of the distance moved or 0.1 mm, whichever is larger *5 | |

| Perpendicularity | Max 0.3 mm / 430 mm | Max 0.4 mm / 610 mm |

| Repeatability | Max 0.1 mm *5 | |

| Standard interfaces | RS-232C, USB2.0 (High speed) | |

| Buffer memory | 2 Mbyte | |

| Command sets | GP-GL and HP-GL™ *4 emulation (selected by menu) | |

| Number of tools | 2 tools | |

| Cutter blade, pen, and tool types |

Cutter blade: supersteel Pen: oil-based ballpoint pen Creasing/scoring tool |

|

| Others | ARMS (Advanced Registration Mark Sensing System), Reverse-side cutting and creasing with ARMS, Copy function, Creasing function, Repeatedly cut function | |

| Power supply | 100 to 240 VAC, 50/60 Hz (Auto switching) | |

| Power consumption | Max. 120 VA | |

| Operating environment | Temperature: +10 to +35 degree C (44 to 95 degree F) , Humidity: 35 to 75% RH (non-condensing) | |

| Guaranteed accuracy environment | Temperature: +16 to +32 degree C (55 to 90 degree F), Humidity: 35% to 70% RH (non-condensing) | |

| External dimensions (W x D x H) *6 |

857 x 780 x 200 mm *7 (33.7 x 30.7 x 7.9 inch) |

1172 x 962 x 200 mm *7 (46.1 x 37.9 x 7.9 inch) |

| Weight | approx. 19 kg (42 lbs.) | approx. 27 kg *10 (60 lbs.) |

| Compatible OS *8 | Windows 10 / 8.1 / 8 / 7 , Mac OS 10.7 to 10.12 | |

| Supported software *8*9 | Cutting Master 4, Graphtec Pro Studio, Graphtec Studio(for Mac) | |

| Certifications | UL , cUL , CE making, FCC-A, EN55022-A, RoHS | |

- *1

- The CB15U or CB15U-K30 cutter blade is used.

- *2

- The CB15U-K30 or CB15U-K20 cutter blade is used.

- *3

- The CB15UA cutter blade is used.

- *4

- HP-GL™ is registered trademark of the Hewlett-Packard Corporation of the United States.

- *5

- When operated with Graphtec specified media and conditions.

- *6

- Tolerance: +/- 5 mm

- *7

- The stand is not included.

- *8

- For more information about Windows and Macintosh compatibility, please check the website or contact with your local representative of Graphtec

- *9

- The software can be used by downloading from Graphtec website.

Accessory

Standard Accessory

| item | Q'ty | Description |

|---|---|---|

| Power cable | 1 | |

| Cutting blade holder | 1 | PHP33-CB15N-HS |

| Cutter Blade | 1 | CB15U-2 (2 blades/pack) |

| Oil-based ballpoint pen | 1 | KB700-BK (Black) and PHP34-Ball (pen holder) |

| Creasing tool | 1 | CP-001, For FC4510-60 only |

| Cling mat | 1 pc each of CM-0004 and CM-0005 for FC4550-50 | |

| 2 pcs each of CM-0004 and CM-0005 for FC4510-60 | ||

| Media positioning plate | 2 | |

| USB CABLE (2.9 m) | 1 | CBL1112ACL2-2.9M |

| DVD/CD-ROM | 1 | User's manual |

| Quick Start Guide | 1 | |

| Usage Precautions | 1 |

* Item has been drsiontinued.

Consumable

Consumable Item

| Item | Model Name | Image | Description |

|---|---|---|---|

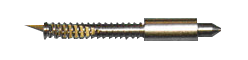

| Cutting blade holder | PHP33-CB09N-HS |  |

Cutting blade holder for CB09UB blade |

| Cutting blade holder | PHP33-CB15N-HS |  |

Cutting blade holder for CB15U type blades without spring |

| Cutting blade holder | PHP35-CB09-HS |  |

Cutting blade holder, metal tip for CB09UB blade |

| Cutting blade holder | PHP35-CB15-HS |  |

Cutting blade holder, metal tip for CB15U type blades without spring |

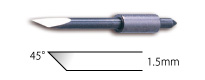

| Cutting blade | CB09UA-5 |  |

Cutting blade, 0.9 mm, 45 degree, with spring, For Vinyl media up to 0.25mm Cutting blade holder : PHP31-CB09*/ PHP32-CB09N* |

| Cutting blade | CB09UA-K60-5 |  |

Cutting blade, 0.9 mm, 60 degree, with spring, For Ultra thin media Cutting blade holder : PHP31-CB09*/ PHP32-CB09N* |

| Cutting blade | CB09UB-5 |  |

Cutting blade, 0.9 mm, 45 degree, For Vinyl media up to 0.25mm Cutting blade holder : PHP33-CB09N / PHP35-CB09 |

| Cutting blade | CB09UB-K60-5 |  |

Cutting blade, 0.9 mm, 60 degree, For Ultra thin media, Cutting blade holder : PHP33-CB09N / PHP35-CB09 |

| Cutting blade | CB15U-5 |  |

Cutting blade, 1.5 mm, 45 degree, For Thick media up to 0.5mm Cutting blade holder : PHP33-CB15N / PHP35-CB15 |

| Cutting blade | CB15U-5SP |  |

Cutting blade, 1.5 mm, 45 degree, with spring, For Thick media up to 0.5mm Cutting blade holder : PHP31-CB15B*/ PHP32-CB15* |

| Cutting blade | CB15U-K30-5 |  |

Cutting blade, 1.5 mm, 30 degree, For Sand-blast rubber or thicker media up to 1.5mm Cutting blade holder : PHP33-CB15N / PHP35-CB15 |

| Cutting blade | CB15U-K30-5SP |  |

Cutting blade, 1.5 mm, 30 degree, with spring, For Sand-blast rubber or thicker media up to 1.5mm Cutting blade holder : PHP31-CB15B*/ PHP32-CB15* |

| Cutting blade | CB15U-K20-2SP |  |

Cutting blade, 1.5 mm, 20 degree, For Sand-blast rubber, Cutting blade holder : PHP31-CB15B*/ PHP32-CB15* |

| Cutting blade | CB15UA-5 |  |

Cutting blade, 1.5 mm, 45 degree, For High intensity reflective film Cutting blade holder : PHP33-CB15N / PHP35-CB15 |

| Cutting blade | CB15UA-K30-5 |  |

Cutting blade, 1.5 mm, 30 degree, For High intensity reflective film Cutting blade holder : PHP33-CB15 / PHP35-CB15 |

| Cutting blade | CB09-E |  |

Cutting blade, 0.9 mm, 45 degree, Economy grade, For Vinyl media up to 0.25mm Cutting blade holder : PHP33-CB09N |

| Creasing tool | CP-001 |  |

Stick type, for cardboard |

| Pen | KF700-BK |  |

Water-based fiber-tip pen (Black) |

| KF700-RD | Water-based fiber-tip pen (Red) | ||

| KF700-BL | Water-based fiber-tip pen (Blue) | ||

| Pen holder | PHP31-FIBER |  |

Pen holder for KF700 series pen |

| Oil-based ballpoint pen | KB700-BK | Pen (black) | |

| Pen holder | PHP34-BALL | Pen holder for KB700 Pen. | |

| Adhesive mat | CM-0002 | Size 435 x 610 mm, 1 mm thick, for creasing | |

| Adhesive sheet | CM-0003-R1A | Double-side coated roll, size 545 mm x 20 m | |

| Cling mat | CM-0004 | Low tack cling mat, size 435 x 610 mm | |

| Cling mat | CM-0005 | Micro suction cling mat, size 435 x 610 mm | |

* It is discontinued.