Intuitive operation

Graphtec greatly values the importance of simple operability - which is reflected through the CE6000's intuitive operation panel, quickly adjustable user settings, and automatic registration mark sensing system to support print and cut alignment.

Large, Backlit LCD screen

Clearly navigate settings of the CE6000 Plus using its large LCD screen (240 x 128 dots) and tactile control panel. This screen is icon driven and supports 10 languages.

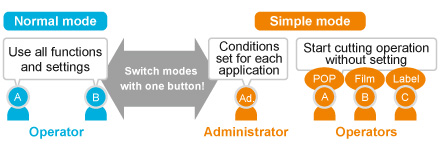

Easier to cut in simple operation mode !

Simple mode

Two set up menus, Simple and Normal, are available and can be chosen by the operator as desired. In Simple operation mode, selecting the media type also sets the necessary cutting conditions.

Saving cutting conditions

8 separate cutting conditions for different media types can be set and stored on the CE6000, making it easy to switch between jobs.

Reliable long length tracking up to 5 m long

The new media stocker ensures a more stable media feed.

Switching the pressure of the center push roller

On the CE6000-120 PLUS, the pressure of the center push roller has two settings to suit all types of media. It prevents media lifting without leaving a trace mark and provides stable long-length cutting.

*CE6000-120 PLUS

Media brake on the media stocker

A brake system is incorporated to assist loading heavy rolls of media properly.

*CE6000-60 PLUS / 120 PLUS

Basket (Option)

The optional basket improves long-length cutting even further.

*CE6000-60 PLUS / 120 PLUS

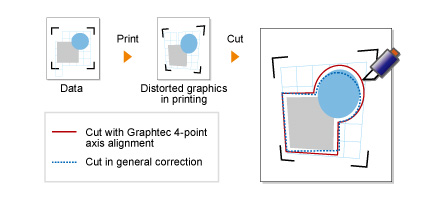

ARMS 5.0 for high precision cutting in the Print & Cut application

ARMS is an abbreviation for Advanced Registration Mark Sensing system, which uses sensors to detect registration marks and performs the AXIS ALIGNMENT.

It is able to adjust received contour cutting data in the cutting plotter to align with the printed image. It enables to significantly improve productivity in the Print & Cut applications that makes stickers or decals.

4-point axis alignment

This feature compensates for any skewing and shrinking on the X and Y-axis using sophisticated algorithms. This leads to more accurate registration and improves the reliability and quality of Print & Cut.

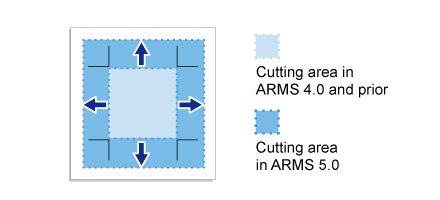

Expanded effective cutting area

The ARMS system expands the cutting area to include outside of the area enclosed by registration marks. This increases production efficiency by reducing media waste.

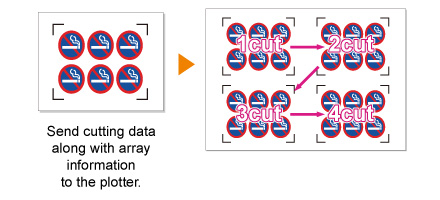

Multiple-mark compensation

When a design is printed using the matrix copy function, the marks are read and contour cutting is repeated for each copy. It can significantly improve productivity for Print and Cut.

* This function is available when supported software is used.

Copy with ARMS

The COPY key allows fast access for making copies of downloaded data. It also supports cutting data including the ARMS control command for processing multiple sheets without a PC.

There are convenience functions of ARMS in the CE6000 Plus series. For details, please refer to "ARMS".